1. `A mass of iron after having undergone the first hammering.' Weale. spec. An ingot of iron or steel, or a pile of puddled bars, which has been brought, by passing through one set of `rolls', into the f orm of a thick bar, and left for further rolling when required for use.

A. 1000 In Wr.-Wülcker Voc. 141/36 Massa, dad, uel bloma.

1584 [cf. bloomery].

1674 Ray Iron Work 127 At the Finery by the working of the hammer they bring it into Blooms and Anconies.

1679 Plot Staffordsh. (1686) 163 They work it into a bloom, which is a square barr in the middle, and two square knobs at the ends, one much less then the other, the smaller being call'd the Ancony end, and the greater the Mocket he ad.

1719 Glossogr. Nova, Bloom, in the Iron-Works, is a four-square Mass of Iron about two Foot long.

1845 New Statist. Acc. Scotl. VI. 79 An extensive forg e for the manufacture of blooms was erected.

1862 Times 12 Aug., Lord Dudley presents numerous specimens of fractured blooms and bars.

1881 Academy 6 Nov. 350 It m ay possibly be a `bloom' from a prehistoric foundry.

1882 Engineer 24 Feb. 133/1 The blooms from the hammer are then heated and rolled down to make puddled bar.

2. Sometimes improperly applied to the `ball' or mass of iron from the puddling furnace which is to be hammered or shingled into a bloom.1865 Derby Merc. 15 Feb., An immense bloom of iron, looking like a huge egg, and weighing 5 cwt., showing the state of the iron as delivered by the furnace.1875 Ure Dict. Arts II. 1013 The bloom or rough ball from the puddle-furnace.1879 Cassell's Techn. Educ. I. 410 After pig-iron has been puddled, the `blooms', as the masses of iron are termed, while still white-hot from the puddling furnace, are dragged to the helve.3. Comb., as bloom-shearing;bloom-hook , an implement used for handling heated blooms;so bloom-tongs ;bloom-smithy , a forge or smithy where blooms are made.1601 Holland Plin y I. 459 This kind of charcole serueth only the Bloom-smithies and furnaces.1831 J. Holland Manuf. Metals I. 18 At the suppression of the bloomaries (or iron smithies) the tenants charged themselves wit h the payment of this rent, which is called Bloom Smithy, or Wood rent.1884 Imp. & Mach. Rev; 1 Dec. 6719/2 A large bloom-shearing machine, capable of cutting steel blooms.3 August

I made a search for literature on iron in GeoRef and found about a dozen sources that seem to summarize what's available.7 August

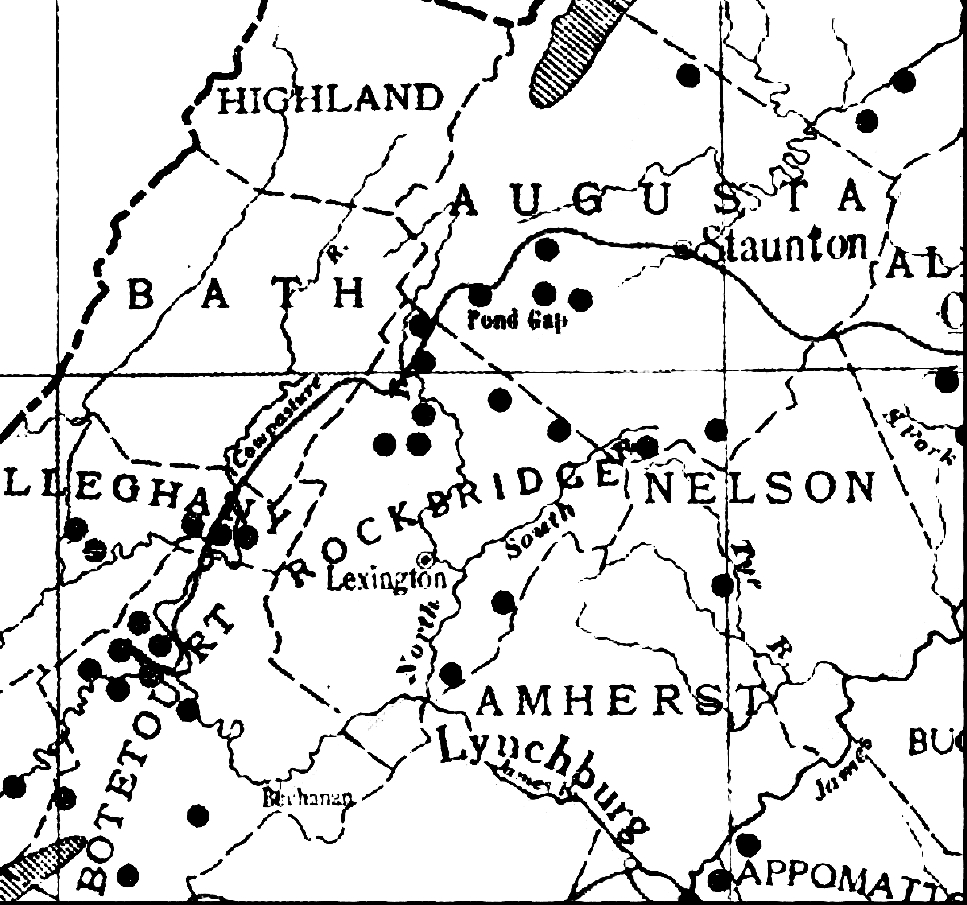

From Bining 1973, who got it from Diderot, section on "Forges ou art du fer" [REF AE25 .E53 vol 4, pp 319-346]:Still further: the plate caption for this illustration identifies the ancony as encrénée, which is not to be found in any of the French dictionaries I examined. And Skip scanned this piece of a map of antebellum furnaces in Virginia:

Skip found Introduction To Early ironworking in Europe WWW Pages

10 August

Seems to me a summary of elements would be a good idea:

- elemental iron (description)

- iron ore:

- furnaces, smelters, forges etc.

- Catalan (description --seems to apply to small furnaces with no tap hole)

- blast (description)

- bloomery (description)

- finery (description)

- chafery

- puddling (description)

- fuel:

- charcoal (description)

- coal

- coke (description)

- kinds of iron (Fe - C alloys)

- cast (description)

- wrought (description)

- steel (description)

- processes: in essence, treated ore is reduced in a furnace

Ironmasters, mentioned in Society for Industrial Archaeology newsletter; also archaeology of coke ovens

11 August

An 1870s Iron Making Primer (Vagel Keller --see also his Industrial Heritage Homepage ("Dedicated to Sharing Information on the History & Modeling of America's Coal, Iron & Steel, and Railroad Transportation Industries") and a page on Mount Savage Iron Works, producer of the first iron rails)Metallurgy for the Blacksmith (a chapter from New Edge of the Anvil, A Resource Book for the Blacksmith, which I've just ordered)

More on phase diagrams is available via Development of Iron/Carbon Compositions from Va Tech (the page for Phase Diagram Basics is a useful overview)

Blacksmith1 (video clip showing a blacksmith heating a bar of iron and hammering it. (2,332K) --requires ability to play MooV files. This and others from NCSU Materials Science and Engineering, and a nice example of distributing multimedia. See Visualizations in Materials Science for the whole thing)

Ancient carburisation of iron to steel: a comment (article from Archeomaterials)

A few more 'iron' references from GeoRef for nearby areas (Augusta, Botetourt, Allegheny counties)

13 August

A large collection of John Hower's articles on the Lebanon Valley PA offers many other items of interest.

Skip brought in a piece of wood from a blowing tub at a furnace in Allegheny County. A quick search for the term via AltaVista turned up only ONE occurrence, but it's in an interesting context of three articles by John Hower:blowing tubs had a few more hits, including

- Development of the Compressor from Ingersoll-Rand

- Historic Iron Furnaces (Emmett A. Conway, Sr., The Olde Forester --see also his page on Iron Furnace Industry in Ohio and a link to material on the Hope Iron Furnace)

Here's what Gordon has to say about blowing tubs:

By the 1780s most American ironmasters used such wooden blowing tubs rather than bellows. A popular early 19th century design had wooden blowing tuibs 5-7 feet in diameter (or sometimes square) with leather-edged pistons having a stroke of 2-5 feet. The maker glued or pinned together segments of 1-inch pine boards to make the tubs. Square wooden piston rods working through stuffing boxes drove the wooden pistons. Many ironmasters arranged blowing cylinders at either end of a walking beam driven by an overshot wheel. These pumped air into a third cylinder fitted with a weighted piston that acted as an accumulator. A sheetmetal pipe carried the air to a clay tuyere loosely fitted into the side of the crucible. The flame at the open top of the furnace pulsated with each stroke of the blast.(Robert B. Gordon American Iron: 1607-1900 pp 105-106) Hopewell Furnace National Historic Site

Bibliography of North American Mining History (Bob Spude)

11 December

Following a lunch with VMI folks to discuss an iron-making project, I did some hunting for designs of small-scale blast furnaces. Nothing definitive has turned up yet, but I did find [via a search for 'bosh near iron'] a good summary of iron smelting at Oswego, OR that's pretty complete, and another document from the same source on the smelters themselves.The question I'd LIKE to find an answer to: how readily can a blast furnace be scaled down to a practical size for the experiment VMI has in mind --or, to put it another way, how small can a blast furnace be made and still work? How much refractory brick? How small a chamber? What sources for blast? A working design would be very helpful, but so far none has turned up.

Other more or less fugitive material [resulting from a search for 'small scale near iron']:

- review of William Rostoker and Bennet Bronson: Pre-industrial iron: Its technology and ethnology (Archeomaterials monograph, no. 1). Philadelphia, Pennsylvania: privately published, 1990 (232 pp. $55 + postage from: Rostoker Inc., 3333 E. 143rd St., Burnham, Illinois 60633, USA.) (Donald B. Wagner)

- The traditional Chinese iron industry and its modern fate (Donald B. Wagner) There's a diagram of a Great Leap Forward small-scale blast furnace.

- Ancient carburisation of iron to steel: a comment (Donald B. Wagner) [noted above somewhere]

- Early iron in China, Korea, and Japan (Donald B. Wagner)

- The Traditional Chinese Iron Industry and its Modern Fate (Donald B. Wagner)

- The earliest use of iron in China (Donald B. Wagner)

- KATAHDIN IRON WORKS STATE HISTORIC SITE (brief summary)

14 December

The question for the VMI folks would seem to reduce to: how small a furnace would be capable of reaching the temperature of 1800 degrees C? What combination of furnace materials, insulation, and air supply would be required? Historical charcoal-fired blast furnaces were not small: Alexander and Street (Metals in the Service of Man, 1976) describe an English example "6 metres high and 2 1/2 meters square on the outside; it could produce 6 tons of iron per day" (see Backbarrow Ironworks illustration, a a related General State of Industry - Coal-Mines and Iron-Works).A visit to Low Moor on Saturday with Steve Riethmiller and Otis Mead raised a lot of questions about industrial processes --how was cok made, for example. The answer is found, in lots of detail, in

AUTHOR Sheppard, Muriel Earley. TITLE Cloud by day, the story of coal and coke and people. PUBLISHER Chapel Hill, Univ. of North Carolina Press, 1947. SUBJECT Coal miners -- Pennsylvania. Coke. Coal mines and mining -- Pennsylvania. Leyburn Library HD8039.M62 U6683