Eventually we'll get to assembly line, and one of the essential texts has to do with disassembly: Sinclair's description of stockyard and packing plant operations from The Jungle, one of those texts people need to have seen. Another essential example: disassembly of a whale from Melville's Moby Dick.

(N.B. that we have the Evans book:AUTHOR Evans, Oliver, 1755-1819. TITLE The young mill-wright and miller's guide : in five parts EDITION 4th ed. PUBLISHER Philadelphia : M. Carey, 1821. SUBJECT Flour-mills. Leyburn-Franklin Soc. TS2145 .E85 1821 LIB USE ONLYAnd there's another book I tripped over that has a lot of basic information on mills and milling, well worth a look:AUTHOR Apps, Jerold W., 1934- TITLE Mills of Wisconsin and the Midwest / Jerry Apps, Allen Strang. PUBLISHER Madison, Wis. : Tamarack Press, c1980. SUBJECT Flour-mills -- Middle West. Mills and mill-work -- Middle West. Leyburn Library TS2135.U62 M532

22 Feb

Electrification

AUTHOR Hunter, Louis C.

TITLE A history of industrial power in the United States, 1780-1930 /

PUBLISHER Charlottesville : Published for the Eleutherian Mills-Hagley

Foundation by the University Press of Virginia, 1979-<1985 >

Leyburn Library HD1694.A5 H76

From Nye's Electrifying America:This hunting pointed me to a number of sources I hadn't found, or hadn't considered in this connection when I had located them previously, likeA factory's form of power determines its maximum size and possible locations. For 250 years water wheels supplied the majority of all industrial energy in the United States. Water poer tied production to the banks of swiftly moving streams and required the construction of dams, channels, and spillways. Water power could not be transported long distances, and required that materials be taken to the power source, often a rather cramped valley... Within the mill, energy had to be transmitted by gears, belts, and pulleys, which lost power at literally every turn. in an economy based on such power transmission, the factory reached an absolute limit on its size beyond which inefficiencies were too great. the mill's form was also dictated by the need to minimize the distance between the flowing water and the work. Buildings were invariably multistoried structures placed as close to the water as possible, usually parallel to the stream. thus water power, not the comfort or efficiency of the workers, determined the structure of early factories. Only in 1870 did steam engines supplant water power as the chief energy source, not so much through a process of replacement of existing facilities as in new plant construction, particularly in the Middle West where the flat terrain made water power less feasible... Electrical power made possible entirely new factory forms. Strictly speaking it did not replace water and steam power but intervened in the transmission process... Industry would not electrify until the electrical manufacturers had efficient and reliable motors that surpassed mechanical systems.

Such motors did not exist until 1884 when Frank Sprague developed one that sparked little and maintained a constant speed, regardless of whether the load changed or not... (pp 193-195)

And another:

...before about 1905 few individual machines operated with their own motors. Factories refused to scrap expensive existing installations and time-tested manufacturing methods just because it was possible to have a costly electric motor directly attached to each machine. Instead, manufacturers preferred to use large electrical motors to drive the system of shafts and belts previously attached to water wheels or steam engines... (pg 199)

AUTHOR Nye, David E., 1946-

TITLE Narratives and spaces : technology and the construction of

American culture / David E. Nye.

PUBLISHER New York : Columbia University Press, c1997.

SUBJECT United States -- Civilization -- 19th century.

United States -- Civilization -- 20th century.

Technology and civilization.

Leyburn Library E169.1 .N816 1997

And power transmission is another set of technologies

that need to be taken into account --shafts, belts... eventually direct

electric motors, but a lot of the late 19th century growth of American

industries was based upon belt drive, of which we have no

experience. See

AUTHOR Rankine, William John Macquorn, 1820-1872.

TITLE A manual of machinery and millwork

IMPRINT London : Charles Griffin & Co., 1869.

SUBJECT Machinery.

Mills and mill-work.

1 > Leyburn-Spec Coll-Rare TJ145 .R2 1869 LIB USE ONLY

Another theme to knit into the subject is the American System of manufacture (at the heart of which is precision and interchangeable parts --starting with [perhaps] firearms, then => sewing machines => typewriters => bicycles, and substantially underwritten by developments in machine tools), which eventually morphed into "Mass Production" (which, as Bucky Fuller notes, is necessarily accompanied by Mass Consumption: 1969 R. B. Fuller Operating Man. Spaceship Earth viii. 117 "As we study industrialization, we see that we cannot have mass production unless we have mass consumption.") The passage through "Fordism" would be interesting to explore. David Hounshell notes that Peter Drucker "long ago maintained that Ford's work demonstrated for the first time that maximum profit could be achieved by maximizing production while minimizing cost", via advances in production technology (1984:10), notably the use of stamped metal components and the assembly line, and management innovations (the Five-dollar [and 8-hour] Day as incentive for workers to stay in the unpleasant conditions of The Line).

From Hunter & Bryan 1991:

The conventional kind of power distribution identified witrh the first industrial revolution was a system of shafts, gears, pulleys, and belting attached to hangers from ceiling or sidewalls, which was called millwork. It was costly to install, difficult and expensive to maintain, inefficient in operation, and inflexible in arrangement... The replacement of this world of whirling pulleys and flapping belts first by slender lines of piping conveying air or water under presure and ultimately by thin wires conveying electrical energy constituted a revolution in the utilization of energy more significant than the development of a new prime mover..." (pp 115-116)A major investigation of the early 1880s covering 55 industrial establishments, chiefly textile mills, revealed that the combined power losses in engines and millwork ranged from 1/5 to 1/3 of the power consumed, with 1/4 as the overall average... In even the best designed and maintained amchine shops, for example, some 40 to 50 percent of the power was consumed in reaching the machinery to be driven. (pp 123-124)

Mention of "the first industrial revolution" reminds me that the essentials of that aren't necessarily understood. Hunter 1979 (in the first of the 3 volumes) summarizes thus:

The key innovation in the Industrial Revolution was the mechanization of hand operations and the use of mechanical power to drive the machinery. (p 161)

The concept of water privilege as a spatial entity is important, and the tale of Lowell MA (founded in 1822) is instructive:

Lowell not only established a new scale and concentration in factory production but it pioneered in the design and execution of a waterpower on a scale that dwarfed all previous enterprises... (Hunter 1979:205) and served as a prototype for Manchester NH and Lawrence MA and Holyoke MA --locations which featured "much the same planned industrial community grouped about the hydraulic system... (p 225)Steam power had been introduced in the Lowell mills in the middle 1840s; its use increased slowly at first, then more rapidly during the 1860s until it outdistanced waterpower a decade later. By the early 1880s twice as much steam power as waterpower was used... (p 287)

It was the turbine that offered significant improvement on the mechanical efficiency of the traditional under- and overshot waterwheel [see breastwheel illustration from Harper's Ferry NPS site] (Fourneyron's 1827 invention, written up in Journal of the Franklin Institute in 1839-40, offered 70-78% efficiency; Ellwood Morris' experiments with Fourneyron's design in JFI 1843; Boyden's work at Lowell in scaling up and increasing efficiency --see outward flow turbines for illustrations [Harper's Ferry NPS site])

The turbine came into its own with the development of hydroelectricity (in the 1890s). Hunter quotes Joseph P. Frizzell in 1894, commenting on the cut-and-try methods of machinists who built turbines (and decrying their lack of mathematical and hydrodynamic knowledge): "It is customary to say that turbines go by water but it cannot be denied that the sale of water wheels goes largely by wind, and the success of wheel makers depends to a much greater extent upon their skill in the use of the latter agency than of the former." (pg 389)

23 Feb

Some passages summarizing Fordism, five

articles on various facets of Fordism (some quite long...) and two

pictures of Frederick W. Taylor:

4. In various scientific and technical uses: A group, set, or

aggregate of things, natural or artificial, forming a connected or

complex whole.

...

b. of artificial objects or appliances arranged or organized for some

special purpose, as pulleys or other pieces of mechanism, columns or

other details of architecture, canals, railway lines, telegraphs, etc.

1830 Herschel in Encycl. Metrop. (1845) IV. 804 Joint vibrations

of a plate and string as a system.

1851 Ruskin Stones Venice (1874) I. viii. 88 Magnificent buildings

have been composed of systems of small but perfect shafts.

1855 Bain Senses & Int; i. ii. Sect.8. (1864) 31 A system of

telegraph wires.

1868 Freeman Norm. Conq. II. ix. 318 The system of beacons, which

has been traced out over a long range of the hill-tops.

1892 Daily News 1 Nov. 6/6 The principal members of the staff are

residents upon the company's system and daily travellers upon the line.

24 Feb

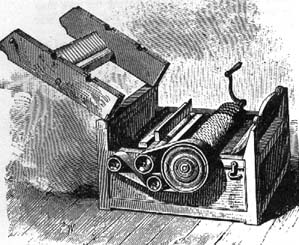

think about this in relation to Taylor a century later:"Whitney watched the cotton cleaning and studied the hand movements. One hand held the seed while the other teased out the short srands of lint. the machine he designed simply duplicated this"

and John's question about other purported inventors [an answer to which seems to point back to Herbert Aptheker's Ph.D. dissertation --H31 .C7 no. 501] led me to Technological Revolution And Prospects for Black Liberation in the 21st Century (Abdul Alkalimat) and Black Labor From Chattel Slavery To Wage Slavery (from Sam Marcy's High Tech, Low Pay). And this summary from http://teach1.cses.vt.edu/Hist3124/ch3.html:

- Eli Whitney patented the cotton gin in 1794. l. Prior to Whitney, only the black seed on long staple cotton was viable, but could not be raised profitably beyond the Sea Islands of SC and Georgia.

- In 1793, only 3 million lbs. of cotton raised in SC and Georgia - by 1811 this increased to 80 million lbs.

- This event (the ability to remove seeds from short-staple cotton) corresponded to the invention of the flying shuttle, power loom, and spinning jenny of the Industrial Revolution in England.

- Cotton farming became a boom activity and expanded into the Piedmont of VA and NC and along the Gulf Coast in AL, MS, and LA.

- Motivated by high prices, southern farmers purchased and cleared new lands, bought slaves to work in the fields, and moved into the middle class.

- New Orleans provided an international export market for short-staple cotton.

27 Feb

After mentioning querns in class yesterday I found some useful

addenda: